Modern digital tools have changed forever how engineers design new products. The development of 3D modeling has revolutionized mechanical computer-aided design (MCAD). It has enabled engineers to develop new products quickly, in collaboration with colleagues around the world, and respond rapidly to changing demands.

We have looked in the past at some of the advantages that 3D design brings to engineers. However, the mechanical aspect of any design is only part of the process. The creation of any device represents the blending of different disciplines, from technical to logistical, and electronic design has its own computer-aided design solution, often referred to by its acronym – ECAD.

ECAD and MCAD

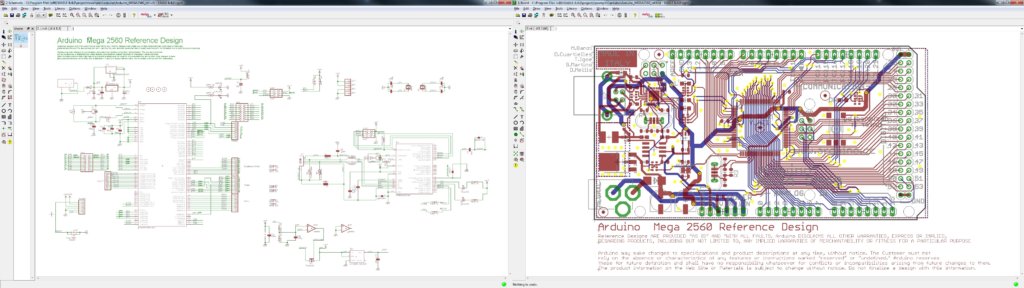

ECAD uses a visual interface to represent the wiring, connections, and components needed to create a functioning printed circuit board (PCB). In contrast to mechanical design, electronic design requires two different elements. The first is a circuit diagram or schematic, which is purely a symbolic representation of the functioning of the circuit. But this schematic does not show the actual PCB itself, nor does it provide the details of how this PCB should be made.

In order to manufacture the circuit, a second drawing is required. For a printed circuit board, this will be a visual representation of the actual layout of the PCB and is created after the schematic diagram has been completed. It will show the bill of materials which is the list of components required. It will also include a layout showing where components are to be placed on the board and how the printed tracks of the PCB are arranged to provide the connection between them. This can then be used by the manufacturer to create the final product.

Image: Sparkfun

Just as pre-made 3D models are available for mechanical components to save the engineer time, so too schematic and layout symbols are available for PCB components, representing both aspects of the design process.

In normal practice, the electronic element of a design is completed before the mechanical, and so there needs to be a sharing of data between the ECAD and the MCAD. Most ECAD software will allow the export of a simple mechanical model of the printed circuit board, sufficient to build it into a full mechanical design.

The Product Lifecycle

If this was the full extent of a designer’s needs then our story would end here. However, the actual design is simply a stepping stone in the complete lifecycle of a device, and the element that ties this entire cycle together is data.

The modern demand for data is huge, from the initial discovery phase during which the engineer conducts research and selects components, to the end-of-life phase when maintainers need to ensure the continuity of the supply chain. Complex data follows the component through every aspect of its life, and enables integration into Product Lifecycle Management (PLM) systems.

This is known as the Digital Thread. This information is vital to the Digital Transformation of businesses across the world and can include everything from basic product characteristics to advanced information on expected performance, recommended maintenance schedules, and end-of-life handling. This data will be vital as the Industrial Internet of Things (IIoT) and Industry 4.0 become more common in the manufacturing environment, and equipment becomes part of a larger system.

We have already seen that ready-to-use models, either schematics for ECAD or full 3D models for MCAD, save engineers huge amounts of time in the design phase. However, by selecting models from trusted sources like Samtec, and choosing the native model format for their chosen CAD platform, engineers are already taking important steps to enable the digital thread and digital transformation in their business. A native CAD model, compared with a generic STEP or IGES format, is pre-populated with the metadata that the engineer needs to integrate this component into PLM software.

Become Part of the Digital Transformation

In this new industrial revolution, data will become as important as individual machines or components and will join every aspect of the process. Without the right data, true digital transformation will simply be impossible. By working with partners like Samtec who can provide this data as part of the complete design package, engineers around the world can embrace the power that data can provide and become more agile, efficient and competitive.

The Resources page of Samtec.com allows you to download mechanical and electrical models in your chosen format. Whether you need traditional 2D drawings, 3D models, or the very latest ECAD files, the Samtec website will help you to be part of the digital transformation.

Leave a Reply