When the Boeing 777 first entered service in 1995, it ushered in a new era for commercial aviation. For the first time, Boeing had worked closely with the airlines in the development of a new jet to ensure it satisfied the needs of the end customer. It was also the first Boeing product to incorporate fly-by-wire technology, the flight control system that had been so successful in military aircraft and Boeing’s largest competitor, Airbus.

More importantly for engineers, the Triple Seven was the first commercial aircraft to be designed entirely using 3D Computer Aided Design (CAD). Using the CATIA system developed by IBM and Dassault, Boeing understood the advantages that designing with computers could offer.

A quarter of a century later, the technology of 3D CAD has evolved hugely, but the advantages remain the same. Using electronic drawings, it is possible for engineers who may be separated by thousands of miles to collaborate on the same design. The ability to change a design rapidly makes the process much quicker, and the visualization tools of 3D CAD software make it easier to review and share information.

Complex Features

In addition, the latest innovations in computing power mean that a digital model can be simulated in a virtual environment. This allows engineers to test and evaluate their design, highlighting problems before a physical prototype is made. The advantages of using 3D CAD software seem overwhelming, so why are more engineers not using this powerful tool?

Traditional 3D CAD software is costly and complex. A system that is comprehensive enough to design an airliner is understandably difficult to use. The investment required for the systems, software and training needed to get the best of 3D CAD can be considerable. In addition to the ease of use is the thorny problem of drawing control. If several engineers are working on the same project, an elaborate system needs to be employed to make sure that all are using the latest version, and whilst one user is making changes, all other users are “locked out”.

However, not everyone is designing the latest airliner or even the latest smartphone. For many users, 3D CAD can be brought to bear on smaller tasks, and the advantages that it gave Boeing can be applied to engineers the world over. The ability to share and collaborate, to design quickly and to show the results easily is very powerful to smaller users.

Not a Specialist?

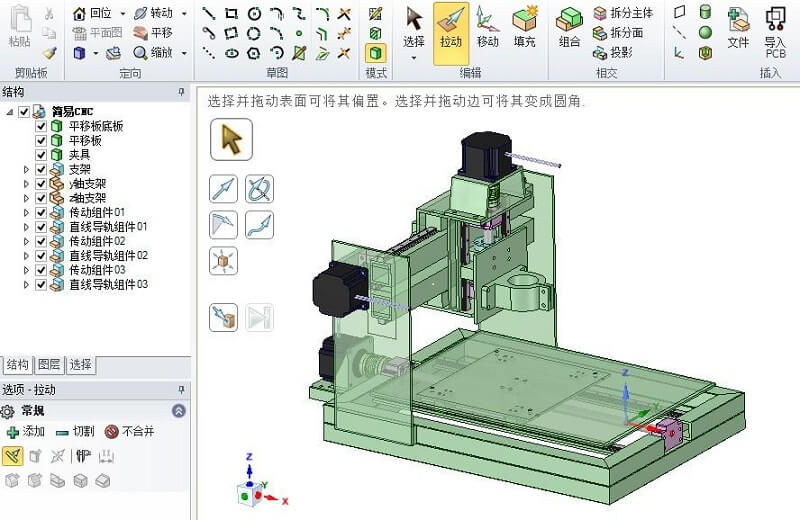

The 3D CAD industry has developed solutions for just this type of user. For every fully-featured software suite such as Solidworks or CATIA that requires training and practice, there is an alternative aimed at the occasional user. Systems like SpaceClaim use a “direct modelling” approach which allows engineers to create models with the click of a mouse. Manipulating a model as if it were a digital lump of clay, systems such as these are giving a whole generation of non-CAD engineers the chance to start modelling. Suddenly, the whole team can contribute to the project, making new product development open and democratic. SpaceClaim even powers the free DesignSpark Mechanical if you want to try before you buy!

Systems like Onshape are taking collaboration even further. Onshape is an online 3D design tool which allows multiple users to view and manipulate the same model in real-time, regardless of their physical location. The heart of Onshape is the database that manages access to the model. Gone are the headaches caused by version control – every user has access to the latest version all the time.

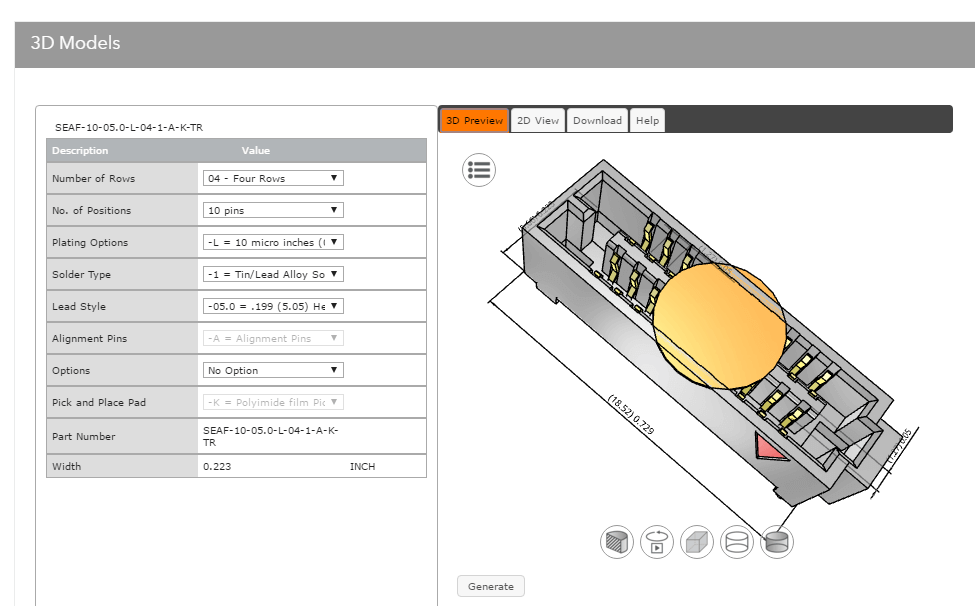

Users do not even need to create a whole design from scratch. There are online communities filled with like-minded designers who are happy to publish their models for use by others. At Samtec, we are also providing accurate 3D models of our components in a choice of digital formats.

Samtec has long understood the power of providing product samples to design engineers, and has embraced the concept of “sudden service” by committing to provide samples within 24 hours. The online delivery of “virtual samples” shortens the design process even further, allowing engineers to try out different solutions in rapid succession. This has revolutionized the approach to customer support, and is the subject of a fascinating case study.

Rapid Prototyping

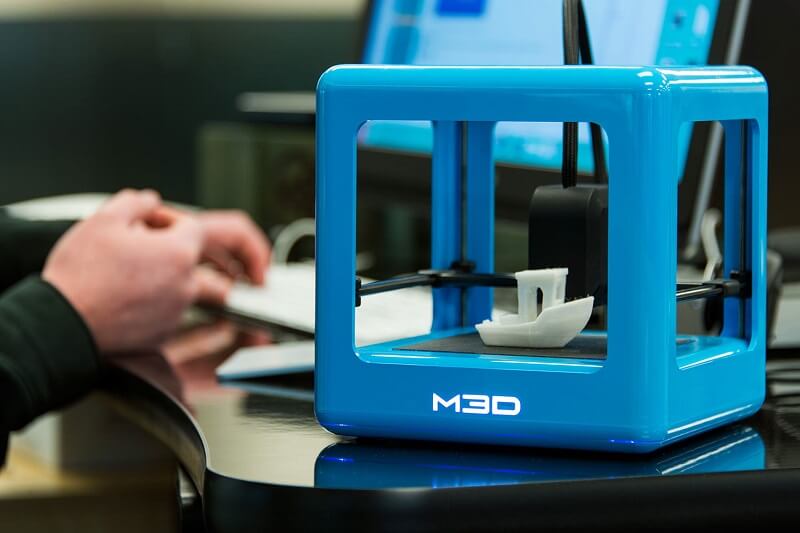

The rise of rapid prototyping means that 3D CAD software now also has a practical output. Over the last few years, desktop 3D printers have become accessible for everyone from students to large businesses. When coupled with easy to use 3D design software, engineers can create a model and print a prototype which can be reviewed, amended and re-printed in a matter of hours. This rapid iteration of design helps to cut down the time-to-market of a new product and allows companies to respond rapidly to their customers’ needs.

The world of 3D design has come a long way since the Boeing 777 took to the skies. It is no longer the preserve of aerospace giants or technology leaders with huge budgets. The ease of use, coupled with a vast online library of reference models, and the ability to create prototypes quickly makes it easier than ever to jump in and start designing. Take a look at how Samtec is making it easier for engineers to make their concepts a reality.

Leave a Reply