Data is the raw material of the future. The advent of the Internet of Things has transformed many activities in the modern world, from growing the food we eat to the way our healthcare is provided. Enabled by the increased capabilities of modern processors and the speed of the latest communication, data will become just as important as steel and energy.

The Internet of Things is allowing machines to share information with each other for the first time. In just one example, machines in the smart factory are collecting real-time information about the status of production, and the health of the machines themselves. By collating this data and analyzing changes, it is possible for the systems within the smart factory to identify potential problems before they threaten its smooth running. Maintenance can be scheduled to minimize the amount of time that a machine is idle.

This same technology is being employed in a host of applications. The agricultural industry has embraced the Internet of Things to grow food more efficiently. Devices range from field-based equipment that monitors soil quality to autonomous tractors that allow farmers to do more with fewer human workers.

The medical industry has been quick to realize the power of wireless and connected devices. The latest developments in miniaturized electronics and high-speed, secure wireless connectivity mean that modern wearable sensors are both lightweight and highly capable. They allow the wearer to be monitored in real-time, meaning that patients with long-term conditions can be treated in their own homes. This alleviates the pressure on hospital beds and enables healthcare to be tailored to the patient’s needs.

Across all sectors of industry, sensors are serving as the eyes and ears of a vast array of equipment. They allow the machines to collect information about the environment around them, but without intelligence, this data is meaningless. With the increased use of sensors, the volume of data being collected is growing quickly. The task of data acquisition and processing is vital to the smooth running of the modern world.

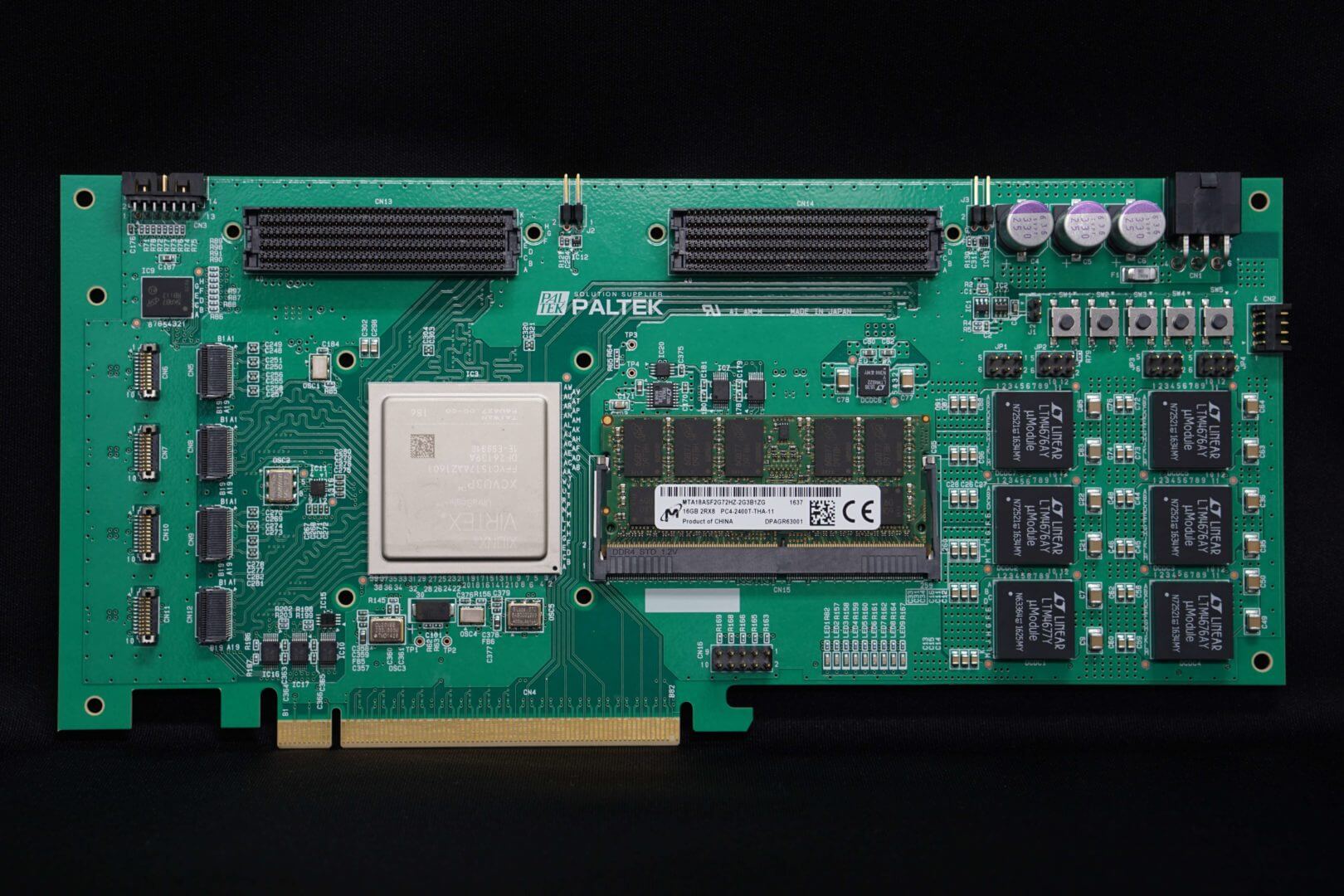

In many cases, this data must be collected, analyzed, and acted upon in real-time. The latest edge computing devices are deployed close to the point of need to minimize delays in transmission. Designers are also turning to Artificial Intelligence and Machine Learning in order to process this torrent of information quickly and accurately. With such high data rates, signal integrity is vital to ensure that data can be acted upon with the lowest possible latency.

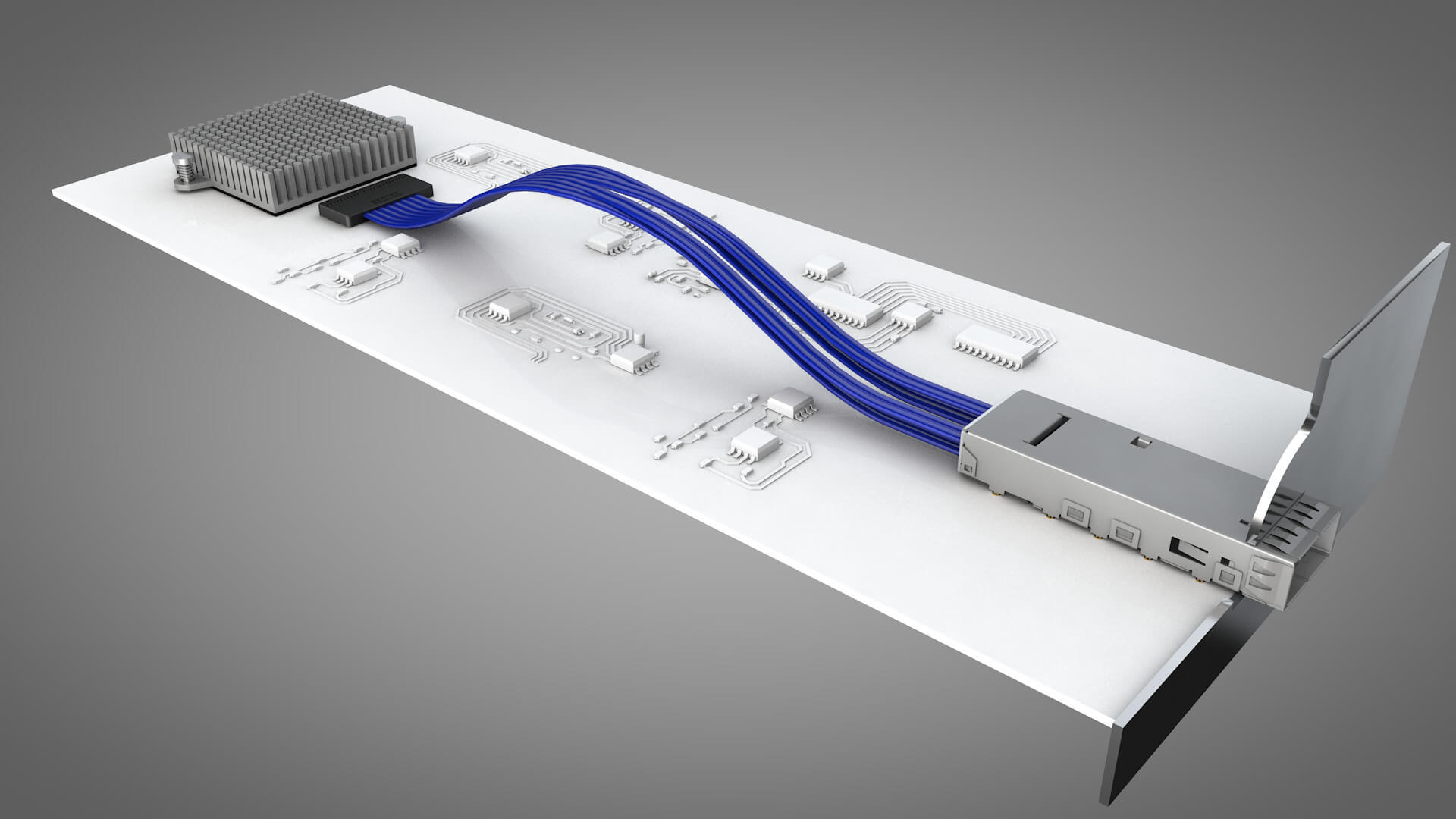

The connectors that are used in data acquisition and control equipment must be capable of transmitting the huge amounts of data that are being generated quickly and accurately. Samtec manufactures a range of connectors that are ideal for delivering the data required by the latest IoT applications, whether in the smart factory, the home, or the hospital. The COM-HPC® standard for high-performance Computer-on-Modules has been designed specifically to handle the high volumes of data that are central to the latest AI and ML applications. The COM-HPC® connector is a 400-pin design based on Samtec’s AcceleRate® family of arrays.

Alongside other options including the high-power solutions offered by the mPOWER® Ultra Micro Power family, the Samtec range has a fantastic selection of connectors that are ideal for handling the data required for the most advanced designs.

For data acquisition applications that must take place in the tough conditions of the smart factory, Samtec also offers a range of initiatives to deliver connectors that will perform reliably in the industrial environment. Severe Environment Testing and Extended Life certification give the engineer all the information they need to design with confidence.

Visit the Samtec Instrumentation page to find the connectivity solution for the most demanding data acquisition applications.

Leave a Reply