This is the fifth and final installment of our series on connector plating FAQs with Phil Eckert, Samtec’s Quality Engineering Manager, and Matt Brown, Principal Engineer. As we’ve mentioned in just about every one of these blogs, the choice and quality of the connector plating (or surface finish) is critical to the success of the component, and it’s a topic that generates many questions from our customers.

Before we get to question set #5, here’s links to the previous four connector plating FAQ blogs:

- #1: Why use gold, why tin, can gold be soldered, galvanic corrosion

- #2: Normal force, temperature rating, number of cycles, tin/lead, plating thickness

- #3: Underplating, lubrication, base metals, voltage/amps

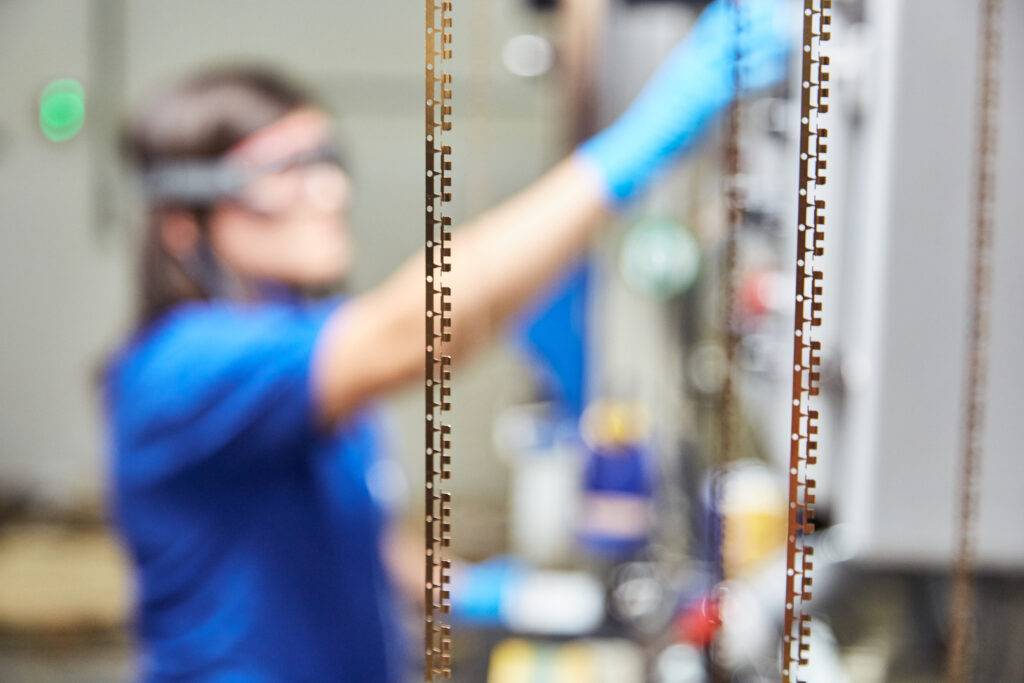

- #4: New technologies, plating shelf life, bandoleer marks, discoloration, solder wicking

One final comment: the goal here is not to write a textbook about connector plating, chemistry, or metallurgy. We want to provide brief, to-the-point answers to the most commonly asked plating questions. And now onto number five …

Does Samtec Use Silver or Nickel Plating?

Samtec does not offer silver plating. Silver is frequently used in very large connectors, where gold is cost prohibitive because of the amount of gold to cover the pin (we don’t want to put an ounce of gold on one connector). Silver is also used in applications that require extremely high temperatures, like high-power connectors. The disadvantage of silver is it reacts to sulfur in the air and forms a sulfate – which is ugly – and will inhibit contact. The good news is this oxidation is easily wiped away, so it’s really a cosmetic issue.

Samtec uses nickel as an underplate, but not as a surface finish. The nickel oxides that form are very resistive, so we don’t recommend them for signal applications. It’s extremely rare to see a nickel surface finish.

Should I Be Concerned About Fretting Corrosion?

Fretting corrosion is a legitimate concern, and it usually involves tin plating in high-vibration environments. Fretting corrosion is a micro-motion issue with movement typically less than .005″ (.127 mm). Just about any material that oxidizes is in danger of fretting corrosion under the right circumstances.

If a mated connector set is moving or sliding, even with minimal motion, a new layer of tin is exposed, which leads to oxidation. If that cycle continues, and the mated connector set is exposed to ongoing micro motions, the connector is continually trying to break through that oxide layer. About once every 12 to 18 months we receive a tin-plated connector set where the contact area has a grey, darkened circular/oval-shaped spot, which is a classic example of fretting corrosion.

The simplest answer to that problem is to switch to gold if possible, and if not, see if you can take steps to control the micro motions in the system?

Does The Lubricity of Matte Tin Plating Affect Crimping Discrete Wire?

Yes, it does. For environmental reasons, many connector companies have replaced Tin-Lead plating with bright acid tin or matte tin. Matte tin does not wear as well as bright acid tin (also called bright tin), so fragments of the matte tin can be deposited onto the wire crimping tools, requiring the tool to be cleaned frequently to prevent the build-up of tin in the tool. Our solution is we’ve kept the plating of our discrete wire connectors as bright tin. Bright tin is harder, slicker, and has much less build-up than matte tin.

What Surface Finish Should I Use For Temperatures Greater Than 125° C?

This is a difficult question because the industry hasn’t settled on an answer yet. There are a number of options available. As we discussed above, silver is well-suited for high temperatures. Palladium-nickel has proven to be a reasonably good alternative for gold, to get above 125° C. Designers who like to stick with gold are looking at new alloying elements. We previously discussed that we alloy our gold with cobalt for hardness. Other alloying elements include nickel or iron, both of which may have the ability to operate at higher temperatures, but test data is still out.

Is A Particular Underplate Recommended For Connector Pins That Are Exposed To Higher Temperature Solders?

Samtec still recommends a 50 µ” minimum nickel underplate in applications that use a higher-temperature solder. The issues with high temp solder typically relate to oxides forming on the surface of the gold or tin, and not migration of base metal through the nickel. Even at higher temperatures, the nickel diffusion layer is going to do its job. We’ve not had applications where customers run into issues where we’ve determined the root cause of the issue is the underplate.

Is It Important To Differentiate Between Bright Tin and Matte Finish Tin Plating?

Bright tin, compared to matte tin, is aesthetically pleasing and will provide a slightly lower coefficient of friction when mating with the other half of the connector. Bright tin will also slightly reduce the insertion force. Matte tin-plated connectors are better suited for the solder reflow process because they are less likely to discolor in elevated temperatures. Matte tin is “purer” in that it doesn’t have organic additives and will probably give you a better solder joint.

If you have questions, please direct them to [email protected].

Leave a Reply