Looking for an odd connector to solve a design challenge? In a previous blog I wrote about some of the odd connectors in the Samtec aresnal that do just that. Today I’m highligting two more odd connectors that may also be just what you need …

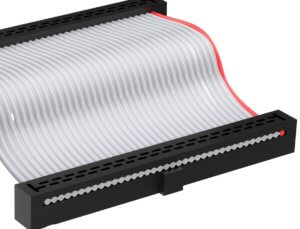

Odd Connector #1: IDC With Countless Design Options And Saves PCB Space

Most IDC cable assemblies are dual-row sockets with side locks on both ends of the plastic body to hold the cap and socket strip base together. While these side locks help ensure the cable assembly will not come apart while unplugging the cable from the board-mounted terminal strip, they do use precious PCB real estate. Also, since the addition of side locks mean the plastic bodies are mold-to-position, they are often available only in industry-standard pin counts, and in dual row only.

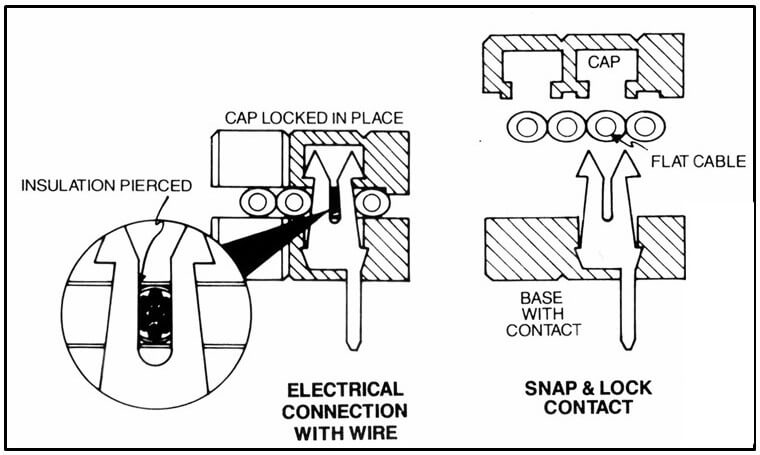

Samtec’s IDSS, IDSD, IDMS, and IDMD IDC cable assemblies are unique in the industry. First, the two-piece plastic bodies do not have side locks, thus saving space on the board. Instead of side locks, the end of the contacts (pins) have outward-facing barbs which, after piercing the cable insulation and making a gas-tight connection with the wire, then slide into the plastic cap, locking the cap to the connector base. IOW, the pins themselves are the locking mechanism.

Second, because the plastic bodies are not mold-to-position, designers can order literally any size connector strip, from 4 – 72 positions with the IDS socket system, and from 4 – 64 positions with the IMS male/plug system. Again, since contacts are the locking mechanism for the plastic bodies, those bodies can be cut to any size requested before the full connector is assembled.

And finally, unlike most IDC assemblies, these connectors are available in both single and double row options, to allow even more design flexibility, as if that were possible.

Odd Connector #2: Extended Right Angle Connectors When You Have More PCB Space

Our TSW series, a .100” (2.54 mm) pitch terminal strip, oozes design flexibility. It’s available in 1-50 pins per row, with up to three rows of pins (i.e., up to 150 I/Os), with four plating options, 28 lead styles, right angle, locking leads, polarization, etc., etc.

Right angle connectors, for 90° (perpendicular) and 180° (horizontal, or coplanar) board-to-board mating, are popular. We have a standard -RA option for standard right angle designs. We also have the -RE option for extended right angle.

With the -RE option, the 90° angle on the pin does not begin until .160” (4.06 mm) beyond the plastic body. With a standard -RA option, the bend occurs .060” (1.52 mm) beyond the plastic body.

We Can Help

Why would a designer want the pin to extend an additional .100” beyond the end of the plastic body, before it bends and terminates to the board? One reason is to cover an oversight or mistake (I’m not talking abou you, of course — please pass this on to somebody else who might do such a thing). If that’s the case, it’s much more economical to purchase a standard connector than change your board.

Sometimes a designer has accidentally designed themselves into a corner. For example, take a look at the connector to the right. About 25% of all Samtec sales are modified products or custom products, with the majority of those being slight modifications to existing products. Things like multiple bends, odd angles, multiple polarizations, stacking bodies, mixing pins, etc., etc.

So if you need a connector that you can’t find on our website or full line catalog, contact our ASP Department and you’ll probably be surprised at how quickly and inexpensively we can modify a product to help solve your problem.

Leave a Reply