As a Southern California native, learning to surf is a must. Traveling elsewhere and telling people you’re from California without experiencing surfing is somewhat a surprise to most people.

So, I have decided to take up surfing. It takes more practice than most people think. I personally love being in the ocean, so learning to surf is natural and comfortable. For others, that may be a challenge. Aspiring surfers may need to learn how to swim in the ocean first

In a similar manner, many enterprises both small and large want to automate their processes. Like learning to surf, there will be start-up challenges along the way. New 5G technologies provide a path to process automation, but learning new hardware, software and system implementations may be obstacles.

As a new surfer I love small waves, but wipe outs on larger waves hurt much more! Adopting new tech can feel like that larger wave, but it is worth it?

Benefits of 5G

Despite all the start-up challenges, adopting 5G technology is the wave of the future. (Pun intended!) When compared to 4G-LTE, 5G delivers up to 100x faster download speeds. It has millisecond latency. 5G also offers up to 1000x more capacity.

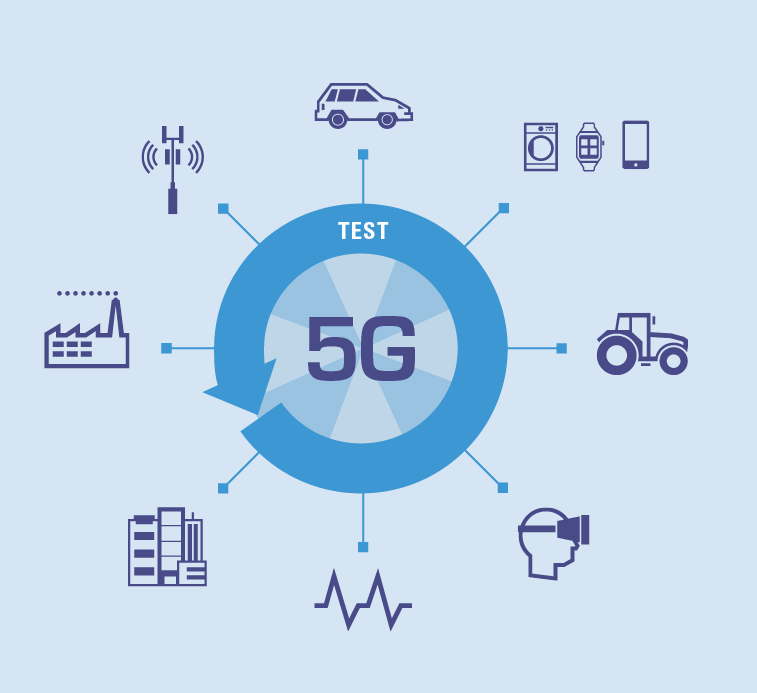

5G will offer increased performance for the consumer, especially for watching the latest TiKTok videos. However, new enterprise-level applications in remote sensing and IoT connectivity well revolutionize industries like agriculture, supply chain logistics, healthcare, energy and more. 5G offers massive machine-type communication (mMTC), which enables tens of billions of wirelessly connected devices .

5G can become the underlying digital fabric connecting all elements of the manufacturing world. 5G promises fast connectivity, more bandwidth than Wi-Fi and 4G LTE and low latency to support for thousands of devices in a small area. These benefits will lead to next-gen smart factories.

Widespread rollout is now a reality. Network providers around the world have established and fast-growing networks.

Overcoming New Challenges

However, for 5G to be deployed successfully in a manufacturing environment, there must be a close collaboration across the enterprise. Legacy enterprise systems and modern IT infrastructure need synergies to fully leverage the new capabilities.

What are some of the challenges to widespread adoptions? Here are just a few:

- Cost: The manufacturing industry has high-cost reduction requirements and will only implement new applications if these have been proven to reduce costs ultimately.

- Safety: Hundreds of connected automated devices on a factory floor can create a hazardous environment for humans.

- Deployment knowledge: Many small and medium enterprises (SMEs) do not have the capacity to resource the learning requirements or the technical ability to capitalize on the potential.

- RF interference: Several objects on the factory floor are already using radio communications.

Samtec 5G Network Application Solutions

As implementation of the 5G network quickly gains momentum, new high-performance devices, systems, and test & measurement equipment are needed to support the ultra-high frequencies and high data rates that technologies like mmWave, Massive MIMO, beamforming and full duplex demand.

Samtec provides 5G solutions in:

- Test and Development

- Remote Radio Heads and Active Antenna Systems

- Network Equipment

- Automotive & Transportation

For more information, please visit www.samtec.com/5G or download Samtec’s 5G Applications Solutions Guide.

Could be a bestie adventure sport hobby.