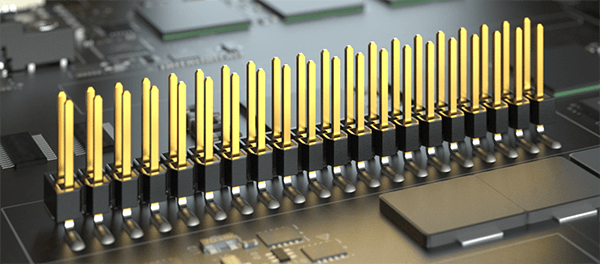

Within the electronics industry, gold is typically king for its corrosion properties (doesn’t oxidize easily), high electrical conductivity, durability, and heat resistance.

Overall, gold will function well in high humidity, high heat, temperature fluctuation, and can be great for high cycle counts (depending on the plating thickness).

This doesn’t mean that gold is without issue. Gold is typically the highest cost option for plating offerings, can be porous if the plating is too thin, and can cause gold embrittlement in your solder joints if your gold plating is too thick.

What is Gold Embrittlement in Solder Joints?

Gold embrittlement occurs when the gold from a contact combines with the tin or tin-lead solder, and the gold content becomes larger than 3% of total weight of the solder.

Crossing 3% causes the solder joint to become weak during thermal cycling due to decreased ductility. A weak solder joint could/will lead to a failure in your system.

It is important to understand that gold isn’t going to destroy your solder joints at all thicknesses. Typically, gold plating below 20-30 µin is considered to not cause an issue. Although, below 10 µin in the contact area is considered to be ideal.

How can Gold Embrittlement be Prevented?

The easiest method to preventing gold embrittlement is to avoid using gold in the tail area (where the parts are soldered to the board) of the contact all together (not to state the obvious).

With Samtec, this is easy to do. Samtec offers several plating styles including Tin, Tin-Lead, Selective Gold (Tin or Tin-Lead on the tails and Gold in the contact area), or Gold plating.

A selective gold plating option is a happy medium for most customers that want gold in the contact area, but do not want it on the contact tails.

Another option is to order any plating style, and then have the contacts solder dipped (tin dipped). This process removes the gold and covers the pin with a layer of solder that hardens onto the pin. This is a common practice within the Mil/Aero industries.

So to answer the question, should you worry about gold embrittlement? Yes, yes you should always make sure that gold on your contact tails isn’t too thick.

If you have any further questions about processing, please contact [email protected].

Leave a Reply