Our blog readers quickly realize that we at Samtec do not view ourselves as another connector company. We are extremely proud of our humble beginnings as we enter our 40th year of business.

Our legacy in Flexible Stacking and Micro/Rugged components and cables forms the basis of who we are.

Our customers depend on our Sudden Service® to minimize risk in prototype and production supply chains. Additionally, our Free Sample Programs support OEMs, ODMs, academia, makers and hobbyists alike.

Continually designers and engineers need system-level solutions instead of just products. OEMs are looking for development partners, not just vendors or suppliers. As we always have, Samtec engineers unique solutions exceeding customer demand and enabling their success.

The Evolution of Technology

The evolution of technology drives Samtec. Hundreds of engineers from our global Technology CentersTM harness application-specific skill sets while collaboratively architecting innovative connectivity solutions based on our core Solution Blocks.

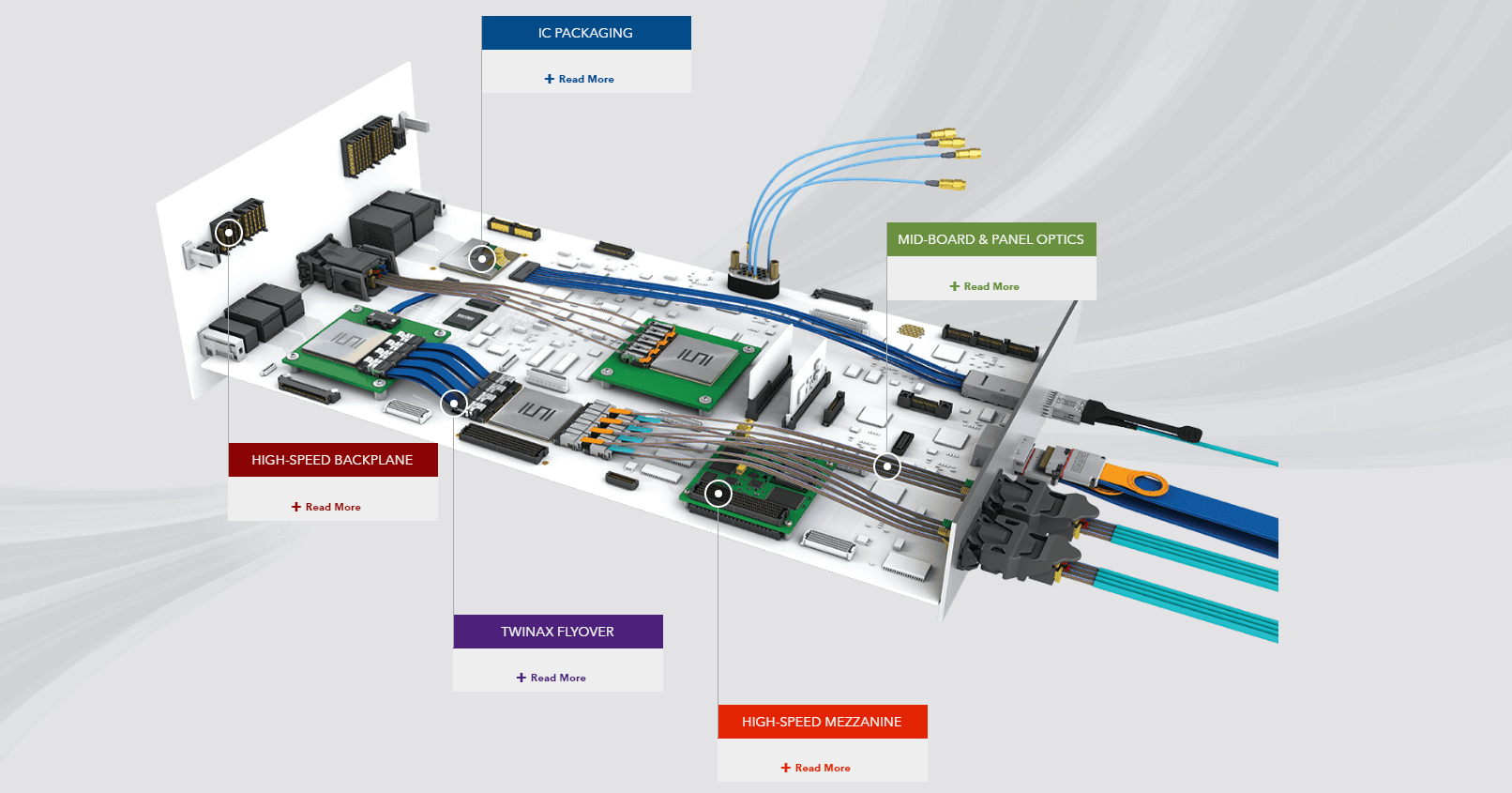

Our Silicon-to-Silicon System Optimization capabilities optimize the high-speed serial path from bare die to IC package and assembly to PCB to connectors and cable assemblies and back again.

These capabilities include:

- Assisting IC layout designers to optimize power and signal integrity of the bare die during the IC design process

- Developing complex, customized IC packaging and assembly solutions enabling maximum IC density, precision and ruggedness

- Enabling PCB designers to create denser, faster PCBs by providing factory and field-based technical support to ensure signal chain optimization

- Providing the products, tools, design expertise and consulting services to link high-speed signal chains between PCBs and through backplanes

- Engineer industry standard and customized copper and optical cable assemblies at data rates up to 28Gbps and beyond

Tapping Into Samtec’s Silicon-to-Silicon Expertise

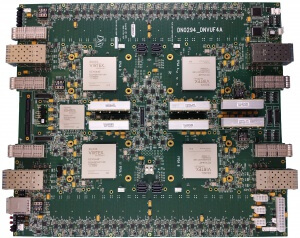

One customer that tapped into these capabilities was The Dini Group based in La Jolla, CA. They develop FPGA development and evaluation boards for ASIC prototyping, code verification and High Performance Computing (HPC).

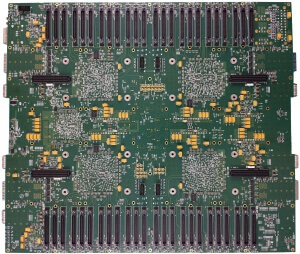

One of their latest solutions is the DNVUF4A ASIC Prototyping Engine. Affectionately called Godzilla’s Butcher on Steroids (GBS), the DNVUF4A features tremendous I/O capabilities via 12 DINI Bank Connectors (DNBCs) per FPGA with a total of 48 in the system. The DNBCs support system expansion, customization and board stacking.

According to the DNBC Specification, DINI mother boards use Samtec SEAF-30-05.0-L-04-2-A-LP-K-TR connectors (Samtec SEAF series). DINI daughter boards use the Samtec SEAM-30-07.0-L-04-2-A-K-TR connectors (Samtec SEAM series).

Dini utilized Samtec’s unique customization capabilities to develop a modified Samtec SEAC series high data rate 38AWG micro coax cable assembly for linking the DNBCs on their mother board and daughter boards.

In addition, the DNVUF4A also contains several Samtec solutions including ERCD, ERDP, ERF8, HQDP, QSH and TSM series solutions.

This is just one example. More and more customers like Dini are working with Samtec to optimize their system performance and signal integrity.

For an overview of state-of-the art capabilities, please download our new Silicon-To-Silicon System Optimization Guide.