Rise of the Machines is a description, a title, and a path. I know, this title might seem worn out, and sound dystopian at the core but I promise in this case it is a good thing.

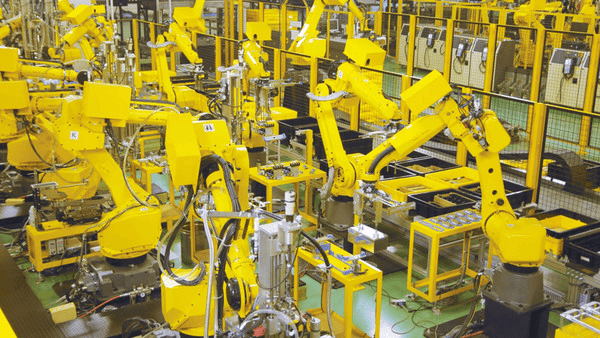

Automation is being used from start to finish in many companies, and it shouldn’t be a surprise that Samtec utilizes automated processes in a lot of areas as well.

So why use Automation?

Well, there are several reasons that a company might choose to employ automation. For instance, in a highly repetitive task where speed and accuracy are key, or if there are hazardous chemicals being used it would make sense to use automation.

Humans are the first choice for an assembly process, but as a process is refined it will often be more cost effective to use automation. A great example of this could be a vision inspection process, assembly line painting, assembling components, etc.

The bottom line here, automation enables companies to place employees in positions that are more enjoyable, safer, and in a position to have less quality issues.

How does Samtec use Automation?

When Samtec was founded, the connectors were larger, gold was cheaper, and tolerances were much larger. However, as with other companies, Samtec had to start using automated processes to build its products.

Perhaps this begs the question of “Why?” Sure, non-automated processes can be used for products that have tolerances that are a lot higher, but as we start down the path to 112 Gbps and beyond that just doesn’t work.

Tolerances for a high-speed product such as AcceleRate® HP or NovaRay® could not be more important as they will play into the overall performance of the connector when in use. This is why using automation to fill pins into the bodies is so important.

Samtec also utilizes automated vision to detect defective products by looking for bent pins, missing pins, etc. This is a process where a large advantage exists to use automation over a microscope and human eye.

These are not the only processes in which Samtec uses automation, and what we currently have will not be the end of it.

Will a manufacturing process ever be without human interaction? That is doubtful in the near future, but for each step that is automated a company will have a higher probability of success in quality and increased speed.

Samtec is ISO-9001 certified and as such, continuous improvement is the name of the game. If you have any questions regarding quality, please contact [email protected] or check out our quality page on samtec.com.

Leave a Reply