Some of my earliest exposure to automotive connectors was while working on my first car. It has been over 25 years since my father and I pulled a beat up old 1968 Mustang to the barn to rebuild. The engine wasn’t special, with the stock inline 6 cylinder motor. (I am pretty sure that is the reason my dad allowed me to make that my first car.) His back in the day had a little more “pep in the step” and he would get in plenty of trouble driving the country roads around Southern Indiana.

When I catch up with Samtec’s Automotive industry manager, Jim Koch, I like to hear about new designs and technologies being developed. Electric vehicles and edge computing are big trends that he is actively involved in.

As we talk about the number of sensors, computing, controls, and options that are actively in design, I begin to get nostalgic. There is something simple about being able to tune the carburetor with one hand while jumping the starter with a screwdriver in the other… relative to waiting on a code from the diagnostics tool plugged in to the OBD port.

A walk down memory lane.

1940

Some of my memories with automotive connectors can trace back to my own experience working on tractors and other equipment. (Chronologically for me this project was after the Mustang, but built almost 30 years prior) I brought home a 1940 9N Ford tractor to help around my small plot of land. This was similar to the 8N I grew up driving at my grandparent’s farm.

Both of these tractors had a flat head, inline 4 cylinder engine with about 18 wire connections (if you included the headlights). Ring connectors and resistor terminal blocks were the high technology “Automotive Connectors” used here. This could be fully rewired in about 4 hours for about $40 dollars.

1968

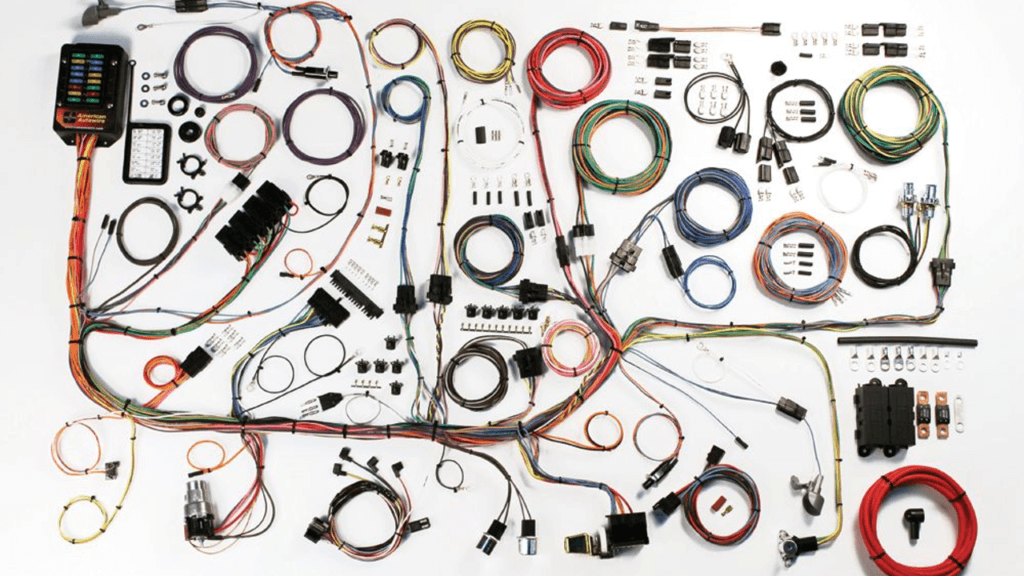

A base line Mustang with limited features took the 18 connections to over 100 with a few hundred feet of cable. There are still many ring terminals, but now many more crimped contacts in bodies with redundant contact points and latching features. (Similar to some of Samtec’s Micro Rugged Cable Assemblies). This full rewire could now cost you about $800 and take more than a day or two to complete.

Many standards bodies were still fairly young with limited publications. This was the first year new cars in the Unites States were required to have seat belts. One of the high tech features added here, around the electronics, was the 8 track upgrade for the sporty models.

1980’s – 2000

I did not personally work on any vehicles through these decades, but more features and options were added from the factory. Others were able to be added through plugging in to the cigarette lighter. Feel free to comment on your favorite add on that maybe you hard wired in to your first vehicle (during any decade).

- Mid 1980’s – Electro Gyrocator/Navigation options and CD players.

- Mid 1990’s – OnStar Service

Today

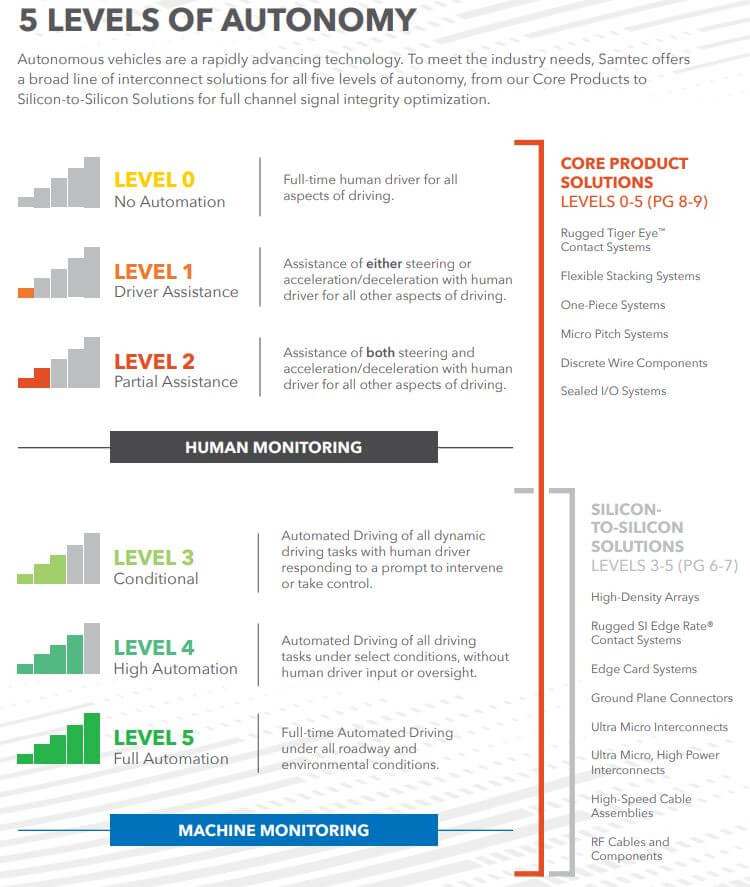

Countless industry standards and categorizations now exist for each type of connector put in a vehicle. When looking at the ISO list dealing with vehicles, the first search came back with over 190 standards/guidelines. Combining this with different levels of autonomy takes the 100+ connectors of the past to well over 300 connections and over 2000 feet of cable.

Connector Supplier had an article a few years back that noted over 150 pounds of wires at that time. Now with adding more computing and sensors on the vehicles to aid in the autonomous driving features, the number of automotive connectors is only going up.

How can Samtec help?

From the technology systems inside the cabin, to sensor and lighting systems outside the cabin, designers can create, build and manufacture with the confidence of Samtec quality and support. Samtec uses proven processes that meet our IATF 16949 certification. Samtec designates these products with an A-Series part number. For each A-Series product, a customer will receive a Level 3 Product Part Approval Process (PPAP) package.

If you are not sure where to start looking for products reach out to our Automotive Connector group. You may also be able to find more information by looking at our Automotive Solutions Guide. or check out our connector families based on the level of autonomy you might be working with.

thanks for sharing this

Electrical Wire Harness Design | Wire Harness Manufacturing ?- SolidPro ES