Samtec’s Ultra Rugged solutions offer reliability and durability to meet the needs of any extreme environment typical in military, avionics, space and submersible applications. Features include rugged contact systems, EMI shielding, high-temp coatings and high cycle life in small form factors with cost and design flexibility.

Our new Ultra Rugged Solutions brochure highlights available products and new technologies on the horizon. This includes Ultra Rugged testing that goes beyond typical industry standards for performance confidence.

ULTRA RUGGED SYSTEMS

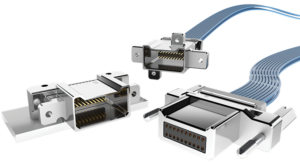

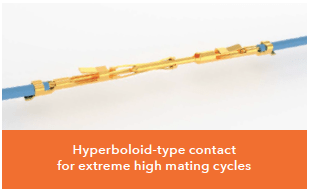

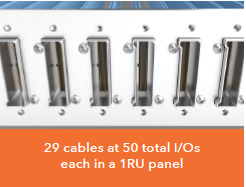

Samtec’s URSA™ I/O rugged power systems feature a hyperboloid-type contact with four points of contact for a reliable connection. It is extremely dense with up to 1,450 total I/Os in a 1RU panel and EMI shielding that limits signal degradation. This cable-to-cable and cable-to-board system boasts up to 40 positions per row on a micro 1.00 mm pitch.

Additional solutions include:

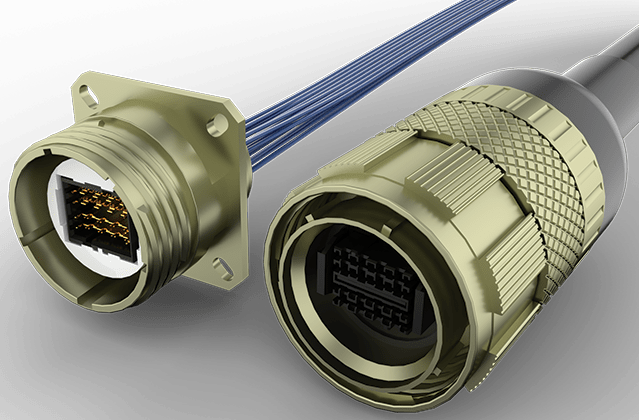

- Samtec’s NovaRay® I/O high data rate cable system is available in a rugged 38999 shell for salt fog resistance to 500 hours.

- FireFly™ optical extreme environment systems are sealed and MIL-Coated with an extended -40 ºC to +85 ºC temperature range.

- Ultra rugged optics are the industry’s most compact with a flip chip assembly for a low profile package in military, avionic and space applications.

- VITA 90 VNX+ solutions feature RF backplane to support 110 GHz, along with SEARAY™ right-angle array and FireFly™ optics as a COTS or modified COTS solution for cost and time flexibility.

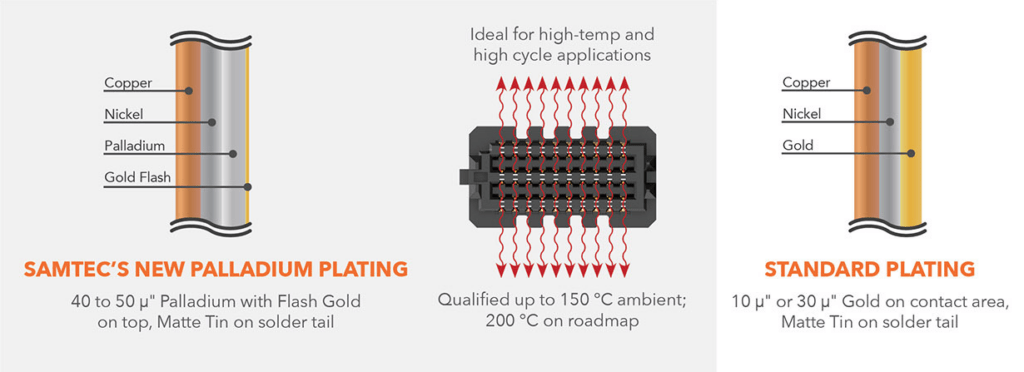

ULTRA RUGGED COATINGS

SureCoat™ coatings provide high-temp, high cycle life and cost optimized solutions for harsh environments. Samtec’s new Palladium plating features flash gold for high-temp applications and is qualified up to 150 ºC ambient with a roadmap to 200 ºC. This is currently available on SEARAY™ 1.27 mm pitch high-density arrays (SEAF/SEAM) with up to 3,000 mating cycles. The roadmap includes availability on other products such as AcceleRate® HP high-performance arrays, LP Array™ low-profile arrays and Generate™ 0.80 mm pitch edge card sockets.

Looking ahead, we have a few new technologies in development:

- A high-cycle “super lube” that can withstand reflow with extreme mating cycles and increased corrosion resistance.

- A next gen surface plating with decreased gold thickness for cost optimization, and increased reliability and life cycles.

ULTRA RUGGED HARDWARE

Samtec’s SureWare™ guide post standoffs (GPSO) allow for 0.035” of initial alignment and assists with “blind mate” for ultra micro, fine pitch mezzanine connectors. They are constructed of 303 stainless steel with a MIL-C-13924 black oxide finish and stack heights from 5 to 30 mm.

Additionally, jack screw precision standoffs (JSO) help reduce component damage during unmating. Precision standoffs (SO) aid with alignment tolerances for Samtec’s high-speed connectors.

ULTRA RUGGED TESTING

Ultra Rugged Testing includes: Severe Environment (SET), Extended Life (E.L.P.™) and Design Qualification. Severe Environment Testing is inspired by military standards to ensure products are more than suitable for military, space, automotive, industrial and other extreme applications. SET qualified products are COTS or modified COTS to help get solutions to market faster. Visit the SET webpage to see a list of qualified products and current available test results.

E.L.P.™ products are tested to rigorous standards to evaluate contact resistance: 10 year MFG and high mating cycles (250 – 2,500). Visit the E.L.P.™ webpage for qualifying products and test results.

All Samtec products undergo Design Qualification Testing, which includes normal force, thermal aging, mating/unmating/durability, IR/DWV, CCC and mechanical shock/random vibration.

For more Ultra Rugged information, check out these other posts:

New Precision Standoffs for Ultra Rugged Applications

Rugged Optical Transceivers For Military, Aerospace, Industrial Applications

Leave a Reply