Robots have been with us for decades, but they are not the cute or futuristic designs that make the headlines or cause a stir at technology conventions. They are the machines that work behind the scenes and are responsible for making many of the products that we use in everyday life.

These industrial robots are relatively unintelligent by today’s standards, but they fulfill important roles. They are designed to perform the same task again and again, with great precision. The automotive industry has been using industrial robots for more than half a century. They do the jobs that are dangerous or boring, such as welding, painting, and assembly.

Creating connector solutions for industrial robots causes headaches for manufacturers, and the key consideration is reliability. When we describe a connector, we normally use mating cycles as the key measure of how long it will last. A mating cycle is defined as the act of mating and un-mating a connector once, and most manufacturers publish a minimum expected number of mating cycles for each type as a measure of its reliability.

It should not come as a surprise if the actual performance of the connector varies enormously when used in the real world. In clean and pleasant surroundings, and when used correctly by experienced technicians, a connector might last far longer than needed. In contrast, if a connector is employed in tough field conditions, and is frequently unplugged in haste, the user might find that it has a far shorter service life than hoped. This could easily be the case when we look at the factory floor in which industrial robots must perform their tasks.

The other problem faced when designing for robots is motion. Robots move quickly, often in multiple directions, and they do so for hours or even days on end. All parts of the robot – its arms and appendages – need to be connected to each other to provide the data, power, and signals that they need to work. Each moving joint represents a problem for designers.

Designing and Testing for Reliability

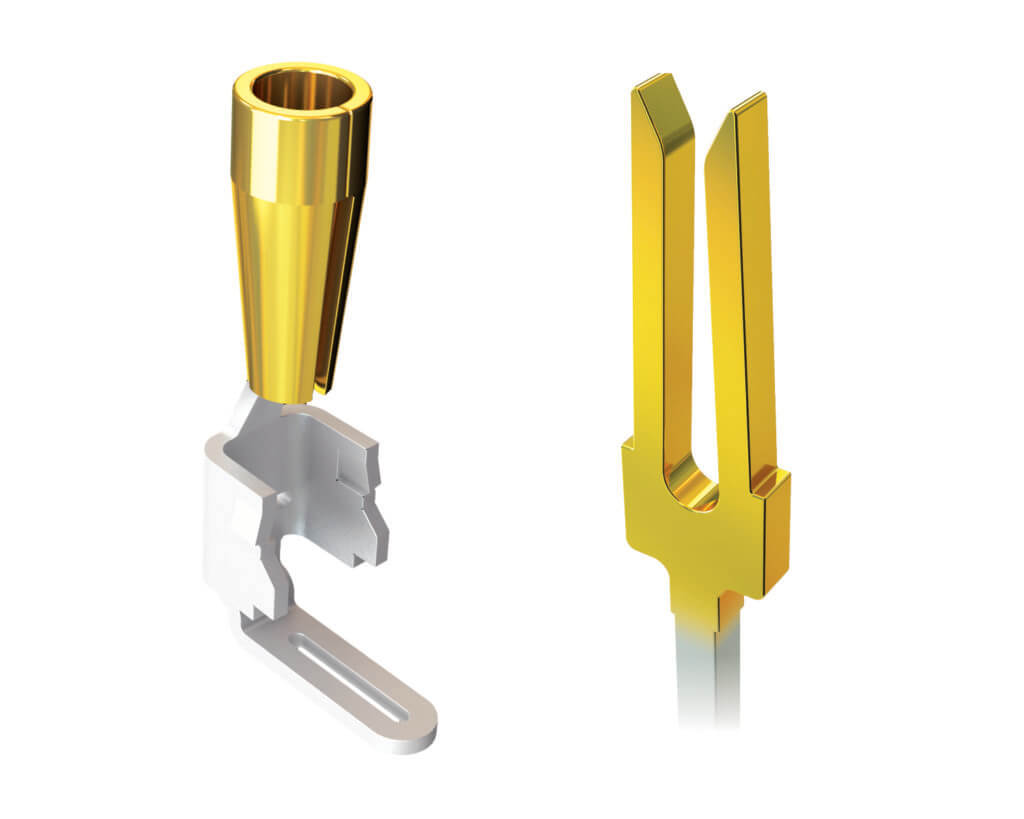

When designing for robots, the construction of the terminals within the connector they use is central to their performance. Most of us are familiar with connectors that use a terminal design that features a traditional plug-and-socket arrangement. This has been with us for a long time entirely because it provides one of the best ways to join two circuits.

The concept behind a conventional pin and socket design is that the fixed pin is inserted into a socket that is slightly smaller. The socket is made to flex sufficiently to allow the pin to enter and create a spring force that ensures contact between the two halves.

One of the advantages of this design is that the pin terminal is relatively easy to manufacture. The pin terminal can be solid, made by machining it from a solid bar, or it can be hollow, created from a flat sheet of metal that is then rolled or formed into a three-dimensional shape. While the different manufacturing techniques deliver their own advantages, the important aspect of this example is that the pin itself is fixed.

It is the socket terminal that provides the flexible element of the design. The socket is slightly smaller than the pin, so the barrel needs to be flexible to accommodate it. As the socket expands to accommodate the pin, a positive pressure is applied to the pin. This is important to ensure good electrical contact between the two halves of the pair and reduces the effects of vibration that might be experienced during normal use.

The positive spring pressure creates other problems, however. To overcome the spring resistance, force is required to mate and un-mate these terminals, known respectively as insertion and withdrawal forces. While the force required for a small number of terminals might be negligible, the same is not true when we consider a connector with many circuits. To mate such a connector successfully, a large amount of force needs to be applied, so it is vital that the operator ensures that the connectors are aligned correctly.

The Risk to Cables

Cables are also at risk when used in industrial robots. When designing for robots, cables need to be protected by ensuring that they do not flex beyond their in-built limits and are not twisted in awkward ways. Even if this can be achieved, cabling is still constructed of metal, albeit very fine pieces of metal wire that are woven together to make a flexible cable. As we have seen many times in history, metal can fail. The constant movement of the cable itself will weaken the wires, seriously affecting their performance and compromising their reliability, even before the cable physically breaks.

However, with repeated movement, the cable will eventually break, at which point the connectors will become vitally important as the cable will need to be removed and replaced. There are some very impressive cables available that offer longer working lives, just as there are high-reliability connectors. I remember working with a multi-core cable that was so flexible that it felt like a piece of cooked spaghetti. But eventually, even this failed with repeated use.

Perhaps the biggest headache when designing for robots is power. Modern battery technology is now far more capable than ever before, thanks in large part to the automotive industry. However, batteries need charging, and until some bright engineer comes up with a way to deliver significant power over a Bluetooth link, connectors are the way to go. And as long as robots keep moving, Samtec will keep thinking up new ways to connect them. For the latest products, download the latest Samtec robotic design guide, or visit our industrial applications page where we explore the world of industrial automation and autonomous robots.

Leave a Reply