Electrical interconnects are used in a wide variety of industries and within a myriad of storage and operating conditions. Because of this, many Electronic Original Equipment Manufacturers (EOEM’s) require extensive testing on the interconnects to ensure they function as intended for their application. Severe Environment Testing (SET) was developed to give designers the confidence needed to design them into their systems.

Origination of the SET Initiative

System designers and engineers are more than familiar with Commercial Off-The-Shelf (COTS) products; however, until recently many in the Military / Aerospace, Space, Automotive, Transportation, Industrial, and Medical industries were not able to utilize them in extreme/harsh applications and environments. These industries require additional testing that isn’t normally conducted on COTS products. The intent of SET is to bridge the gap between a full MIL-STD product and a COTS product. SET provides system designers and engineers the additional level of confidence that the COTS product will function in their application.

Severe Environment Testing

SET was developed using VITA 47.0 – 47.3 and feedback from industry leaders concerning test information on COTS products. A standard qualification test is the combination of tests such as Low Level Circuit Resistance (LLCR), Humidity, Temperature Cycling, Dielectric Withstanding Voltage (DWV), and Mechanical Shock and Vibration. SET takes these standard qualification tests and expands the specifications required to pass the test. By doing so, this proves to the designer that the connector can be used in severe environments.

Here is an example of the SET Report for the Samtec SEAF, SEAM mated connector set. Note this is a typical SET Report.

Mating / Unmating / Durability

It is essential that a connector set can be mated and unmated without a degradation in the signal. Mating / Unmating / Durability demonstrates the capability of the connector set to perform as designed even when the conditions it is subjected to are not ideal. Mating / Unmating / Durability are common in Standard Qualification tests, but with SET the conditions have been intensified. In a standard mating / unmating / durability test, the Relative Humidity (RH) is held at a range of 90 – 98% for a duration of 10 days with 100 mating and unmating cycles at a temperature of +25°C to +64°C. For SET, the RH is increased to 100% with 250 mating and umating cycles for 10 days (240 hours) at a temperature of +25°C to +64°C.

Low Level Circuit Resistance (LLCR) is used as the baseline for this test before it begins. The connectors are then measured for mating/unmating forces, cycled 250 times, and LLCR is tested again. If the connectors have a max delta of less than 15 mΩ they will move to the next test sequence. The remaining test sequences involve Thermal Shock per EIA-364-32, LLCR, Humidity, LLCR, and Mating/Unmating Forces.

Temperature Cycling

Another critical aspect of any environmental test involves ensuring performance of the connector set when exposed to temperature shock. Temperature Cycling assesses the connector’s ability to withstand extreme temperature changes. This test is important where the conditions in which the system operates could change within a matter of minutes.

Normally, a thermal shock test takes a connector set from -55°C to +85°C through 100 cycles with a 30 minute dwell at each temperature. The SET version of this test increases the temperature range to -65°C to +125°C through 500 cycles with a 30-minute dwell at each temperature. During the course of this test, the parts are tested for LLCR to look for increases in resistance through the system.

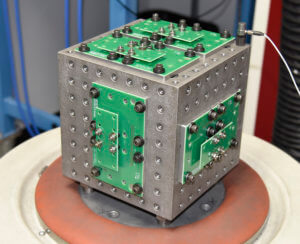

Mechanical Shock / Random Vibration / LLCR and Event Detection

The overall goal of Mechanical Shock / Random Vibration testing is to measure a connector set’s performance under exposure to a series of mechanical shocks and random vibrations. For mechanical shock, the standard version of this test uses a 100G Peak Shock for 6 milliseconds, half-sine, the SET version uses 40G Peak shock for 11 milliseconds, half-sine. LLCR is used before and after the test to gage the effects of the test and to look for changes in the contact system resistance.

The standard random vibration test uses 7.56 gRMS for 2 hours per axis; the SET version of this test using 12 gRMS, 5 – 2000Hz for 1 hour per axis. During this test, event detection is used to continuously monitor the contact set for discontinuities during the vibration test.

Non-Operating Class Temperature

It is important to know the limits of a product, but it is also important to know at what temperature range a product can operate at peak levels. For Non-Operating Class Temperature testing, the product is Low Level Contact Resistance (LLCR) tested, exposed to -55°C to 105°C for 100 cycles, then tested for LLCR again, exposed to -65°C to 125°C for 100 cycles, and finally tested for LLCR again.

Assuming the product maintains a delta of <= 5 mΩ for LLCR from the start of the test to the end, it is considered to be a stable product for those temperature ranges.

Electrostatic Discharge

Electrostatic Discharge (ESD) is not typically tested for electrical connectors; in severe environments, however, there are times when system designers need to know how the components will handle ESD. During an ESD test, the connector is tested mated and unmated with visual inspections before and after testing to determine if damage occurred. For this test a visual inspection is sufficient to determine if the connector passed. Connectors are passive devices, with no active components, and the only damage that could occur would be to the plating.

This test is based off of EN61000-4-2 from VITA 47. The ESD events range from 0 to 15 kV as discharged through a 150 – pf capacitor through a 330-ohm resistor. The connectors are exposed to 5, 10 and 15 kV (10 times at each level), and then are visually inspected for damage.

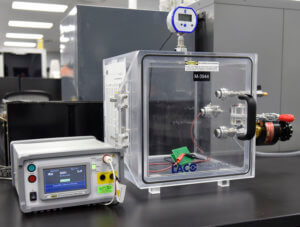

DWV at Altitude

Dielectric Withstanding Voltage (DWV) is a common electronics test, but testing at an altitude of 70,000 ft adds to the difficulty of the test. In a typical DWV test, the connectors are tested by applying the testing voltage for 60 seconds. The part is considered to pass if there were no electrical arcs, and testing voltage = .75 x breakdown voltage.

For DWV at Altitude, the test is conducted in an altitude chamber to simulate an altitude of 70,000 feet with a test voltage at 300 VAC. Assuming the connector sets do not electrically breakdown, they are considered to have passed the test.

Conclusion

The Severe Environment Test was developed by Samtec for system designers and engineers seeking additional qualification data for COTS products being used in severe environments. These tests go beyond the standard qualification tests conducted on COTS products and prove the capability of the connector set to operate in severe environments.

Samtec is publishing all of its data on Severe Environment Test reports for several popular product series at www.samtec.com/set.

Mating connector systems that have been tested, or are in-process, include:

- SFM, TFM Micro Rugged Tiger Eye® System| SET Report

- SEAF, SEAM High Density Arrays, 1.27 mm Pitch | SET Report

- LSHM Micro Rugged Hermaphroditic Connector | SET Report

- SSM, TSM 2.54 mm Pitch System | SET Report

- FTSH, CLP 1.27 mm Pitch System | SET Report

- Click here for a complete list of SET products, including products in testing.

Other articles that may be of interest:

- Severe Environment Testing for Connectors

- A Deep Dive into Severe Environment Testing

- A Deep Dive into Severe Environment Testing (Part II)

- What is Outgassing and How is it Tested?

- Connector Thermal Cycle Qualification For Military and Avionic Environments

- Samtec, COTS, and Mil/Aero

- Samtec Technical Experts to Present at Embedded Tech Trends

For more information concerning SET, please email [email protected].

About The Author

Brian Niehoff is a Technical Marketing Engineer at Samtec. With over 19 years in the electronics industry, Brian has held a variety of rolls including engineering, qualification testing, environmental compliance, marketing, and entrepreneur. Brian is using this experience to expand connector knowledge through the electronics industry, and develop Samtec’s growing customer base.